Advanced Ceramic Products at a Glance(Classified by method for formation/application)

| Shape Forming | Appearance | Intended Application | Raw Materials | Finished Products |

|---|---|---|---|---|

| Cold Isostatic Press (Rubber Press) | Non-porous (Tight) |

|

Alumina | Alumina CIP (Rubber Press) Products |

| Magnesia | Magnesia CIP (Rubber Press) Products | |||

| Zirconia | Yttria Stabilized Zirconia CIP (Rubber Press) Products | |||

| Aluminum Titanate | Aluminum Titanate CIP (Rubber Press) Products | |||

| Injection Molding | Non-porous (Tight) |

|

Alumina | Alumina Injection Molding Products(Crucible for Chemistry Laboratory ) |

|

Non-porous & Heat-Resistant Alumina Injection Molding Products(Refractory Ceramic Sagger) | |||

| Press | Porous/Non-porous (Tight) |

|

Alumina | Press Forming Products(Refractory / Crucible / Sagger / Parts for Sintering Apparatus ) |

| Magnesia | ||||

| Zirconia | ||||

| Mullite | ||||

| Extrusion | Porous |

|

Alumina | Alumina / Magnesia / Silica Extrusion Molding Products(Ceramic Insulators for Heaters) |

| Silica | ||||

| Non-porous (Tight) |

|

Various Materials | Extrusion Molding Products(Thermocouple Protection Tube) | |

| Rammer molded product | Porous |

|

Alumina | Porous ceramics (alumina, mullite, magnesia, zirconia, silica) Rammer molded product |

| Magnesia | ||||

| Zirconia | ||||

| Mullite | ||||

| Silica |

Advanced Ceramic Products at a Glance(Classified by materials / products)

Alumina ( Al2O3 ) Crucible, Plate (Setter / Lid) and Sagger (Boat / Rod)

| Our Products |

|---|

|

| Features |

| The most popular ceramics achieving higher than average level of resistance to heat, chemical attack, thermal shock (spalling), intensity and wear, in addition to being of low cost. |

| Intended Application |

|

|

Magnesia (MgO) Crucible, Plate (Setter / Lid) and Sagger (Boat / Rod)

| Our Products |

|---|

|

| Features |

|

Having high melting point, large thermal conductivity, and good electrical insulation in high temperature. Showing excellent resistance to chemical attack, especially wet corrosion resistance against basic materials such as slag or lead, magnesia products are widely used as metal melting crucibles or as temporary ovens in the semiconductor sintering process. |

| Intended Application |

|

|

Zirconia (ZrO2) Crucible, Plate (Setter / Lid), Sagger (Boat / Rod) and Ring

| Our Products |

|---|

|

| Features |

|

Being of high level of intensity and fracture toughness, the zirconia products are the most popular materials for wear resistant or shock resistant parts. Having unique features which differ from that of alumina in response to metals. |

| Intended Application |

|

|

Aluminum Titanate (TiO2・Al2O3) Crucible, Plate (Setter / Lid) and Sagger (Boat / Rod)

| Our Products |

|---|

|

| Features |

|

Their coefficient of thermal expansion being nearly zero, excellent in thermal shock resistance. Will not crack even when heated to 1,000 degrees Celsius and subsequently thrown into water. (Sample size: 20x25x100 ) In metal dissolution, show excellent non-wetting behavior in contact with fused aluminum and gold. |

| Intended Application |

|

|

Ceramic Insulator/Pipe Insulation (MgO / Al2O3 / SiO2 / Mullite)・Thermocouple Protection Tube (MgO / Al2O3 / Mullite)

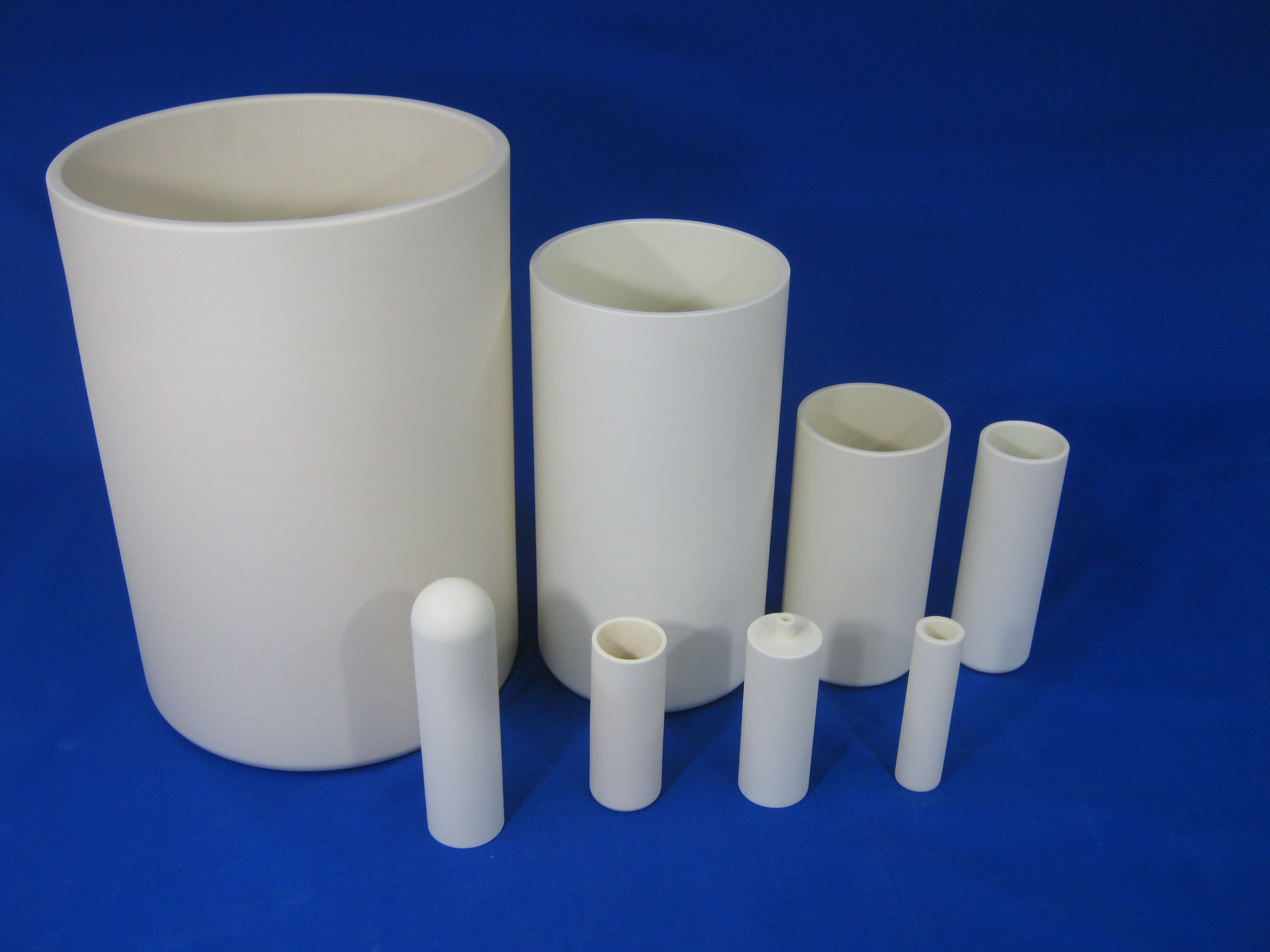

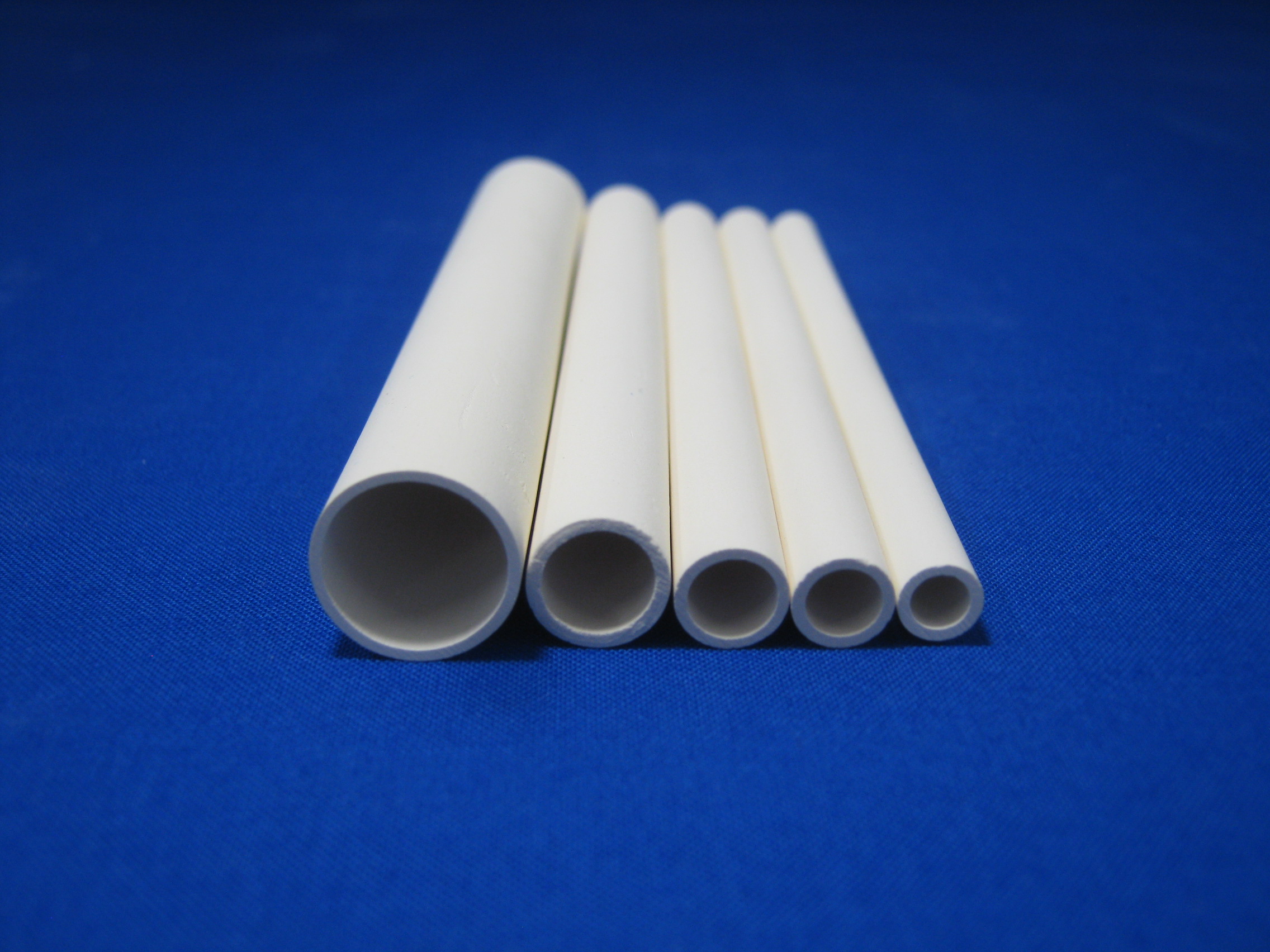

| Our Products |

|---|

|

| Features |

|

Having a high feasibility of mass production of the pipe insulators, the extrusion method will attain a low cost manufacturing. ※ Thermocouple Protection Tube available (Alumina / Mullite / Magnesia) |

| Intended Application |

|

|

Porous ceramics (alumina, mullite, magnesia, zirconia, silica)

| product name |

|---|

|

| Characteristic |

|

Porous ceramics are ceramics that have countless pores inside. Ceramics have low thermal conductivity due to their porous nature, are lighter than metals, and have high heat resistance and thermal shock resistance. Maruwai Yano Ceramic Works can provide large-scale porous ceramic production. Maximum production size Φ720×1260H (for porous alumina crucible) |

| Shape/Application |

|

Facility