Features

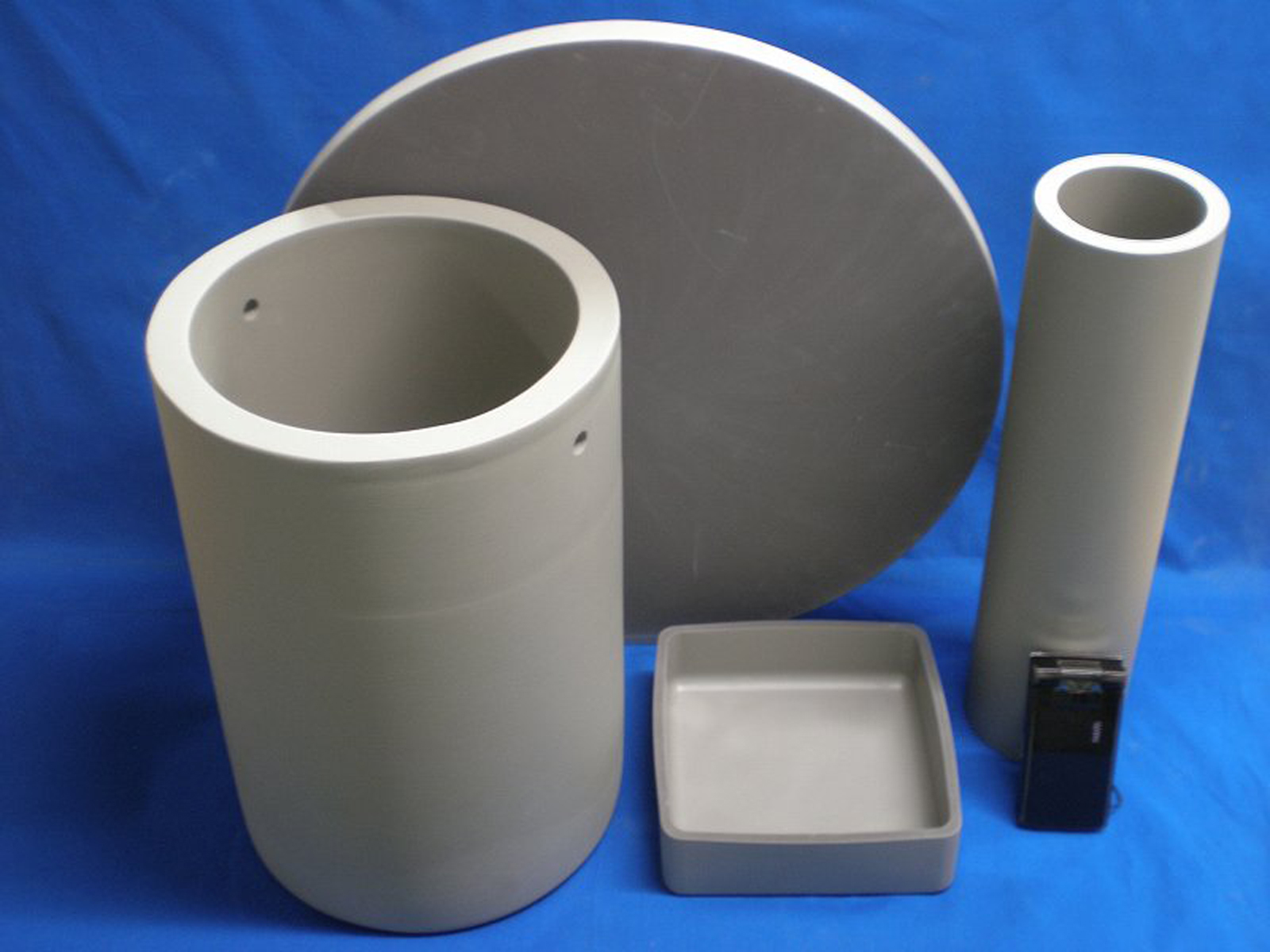

CIP (Rubber Press) Products are highly and homogeneously condensed non-porous products because they are made under the ultra-high pressure in all the directions.

Rubber molds, which are suitable for smaller quantity production but less expensive, are used in the CIP manufacturing process.

Aluminum Titanate CIP Products are

- Excellent in thermal shock resistance, because their coefficient of thermal expansion are nearly zero.

- Depending on their physical shapes, will not crack even when heated to 1,000 degrees Celsius and subsequently thrown into water.

- Show excellent non-wetting behavior in contact with fused aluminum.

Table of Physical Properties

| Product group | FTA-PS | FTA-W | |

|---|---|---|---|

| Materials | Aluminum Titanate | ||

| Appearance | Non-porous | ||

|

Chemical Ingredients (Wt%) |

Al2O3 | 50% | 55% |

| TiO2 | 40% | 40% | |

| SiO2 | 8% | 3% | |

|

Specific Gravity (g/cm3) |

3.1 | 3.3 | |

|

Water-absorption Rate (%) |

1 | 1~2 | |

|

Thermal Conductivity (W/mk) |

– | – | |

|

Flexural Strength (MPa) |

10 | 30 | |

|

Refractoriness (℃) |

1000 | 1500 | |

|

Thermal Shock Resistance (℃/hr) |

1000 | 1000 | |

| Color Appearance | Grey | Light Grey | |

| Intended Application |

Metal Melting Crucibles Setters Sintering container(Battery materials / Electronic parts) |

Metal Melting Crucibles Setters ladle Sintering container(Battery materials / Electronic parts) |

|